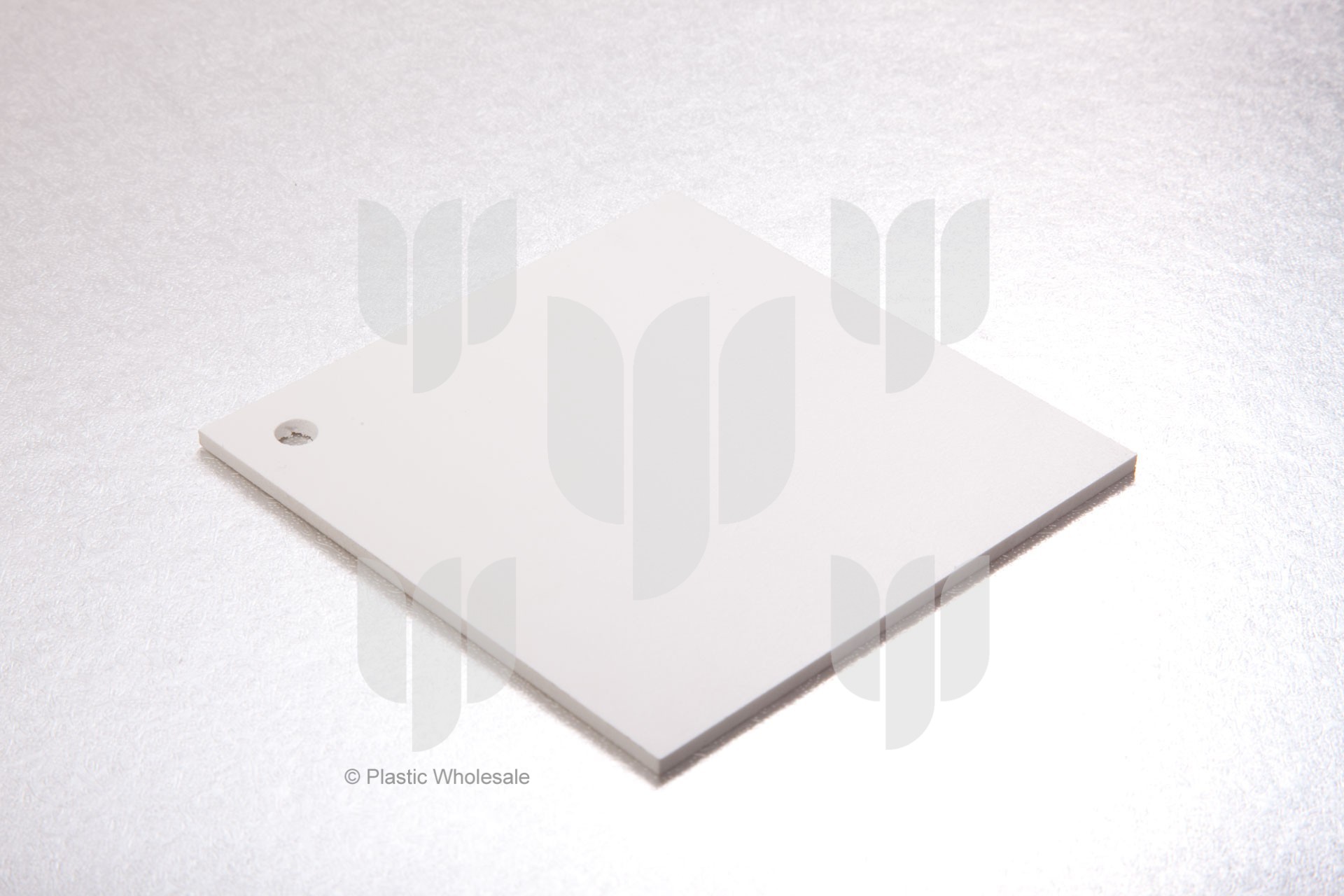

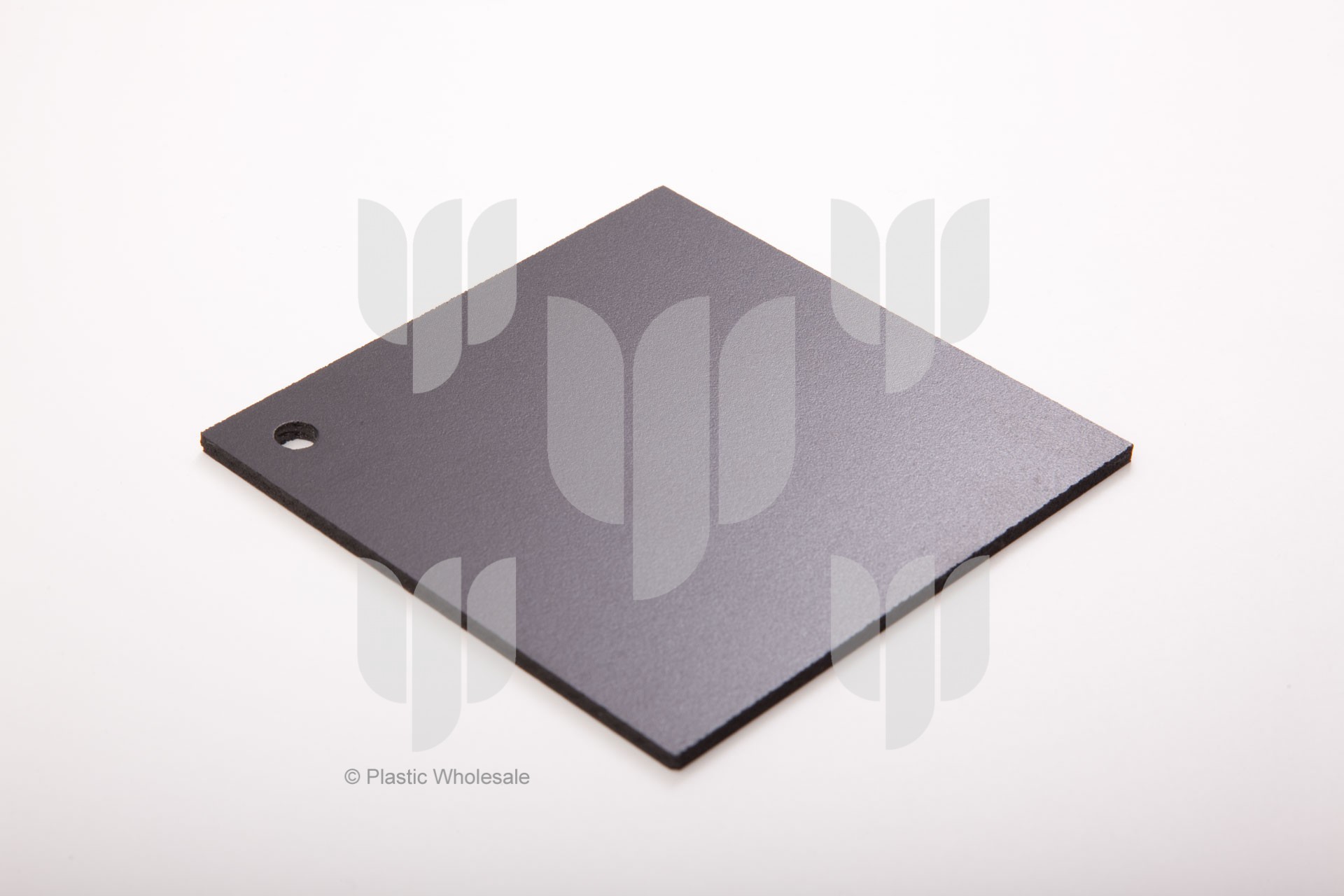

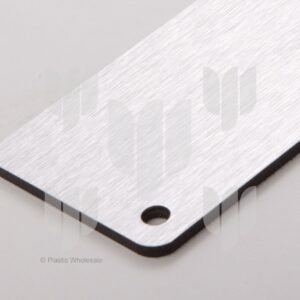

About Foam PVC

Foam PVC combines low density with high rigidity and good sound and heat insulation.

It offers several distinct advantages over solid PVC sheets – including being approximately half the weight, a more effective thermal insulator, easier to handle, vibration and oscillation absorbent, and more cost-effective per unit area.

It is used for advertising signs and displays, in construction, and for many miscellaneous applications such as transport containers and model making.

Download datasheet (144Kb)

Download datasheet (144Kb)

History

1835 – PVC is discovered by accident by Henri Victor Regnault after exposing vinyl chloride to sunlight. It would be re-discovered in 1872 by Eugen Baumann

1930s – The first PVC foam material designed for a marine environment, consisting of a PVC and isocyanate blend, is created in Germany. It is rumoured that it was used in German E-boats and the Bismarck battleship

Applications

Foam PVC offers excellent processing qualities in addition to light weight, high rigidity, moisture resistance, and low flammability. It is used for the following:

- Advertising: Foam PVC is used by advertisers for signs, displays and exhibition stands, and as photograph backing

- Insulation material: Foam PVC provides excellent heat and sound insulation and is used as sub-frame material in double-glazed windows

- Construction: Partitions, wall cladding, facades, interior decoration and air-conditioning ducts are constructed from foam PVC, which can be painted, printed, engraved or milled to specification

- Shop fitting: Shop counter designs incorporate foam PVC, which is also used to make decorative wall panels

Foam PVC is also used for transport containers and in model-making, where it is popular for being easy to cut, shape and paint.

Key Properties

General

Density relative to water (=1), 0.75

Water absorption (24 hrs), 0.50% – 0.80%

Thermal

Thermal Conductivity, 0.06 W/mK

Vicat Softening Temperature, 75°C (167°F)

Mechanical

Tensile Modulus of Elasticity, 1300 MPa

Tensile Strength at Break, 20%

Yield Stress, 20 MPa

![]() Download datasheet (144Kb)

Download datasheet (144Kb)