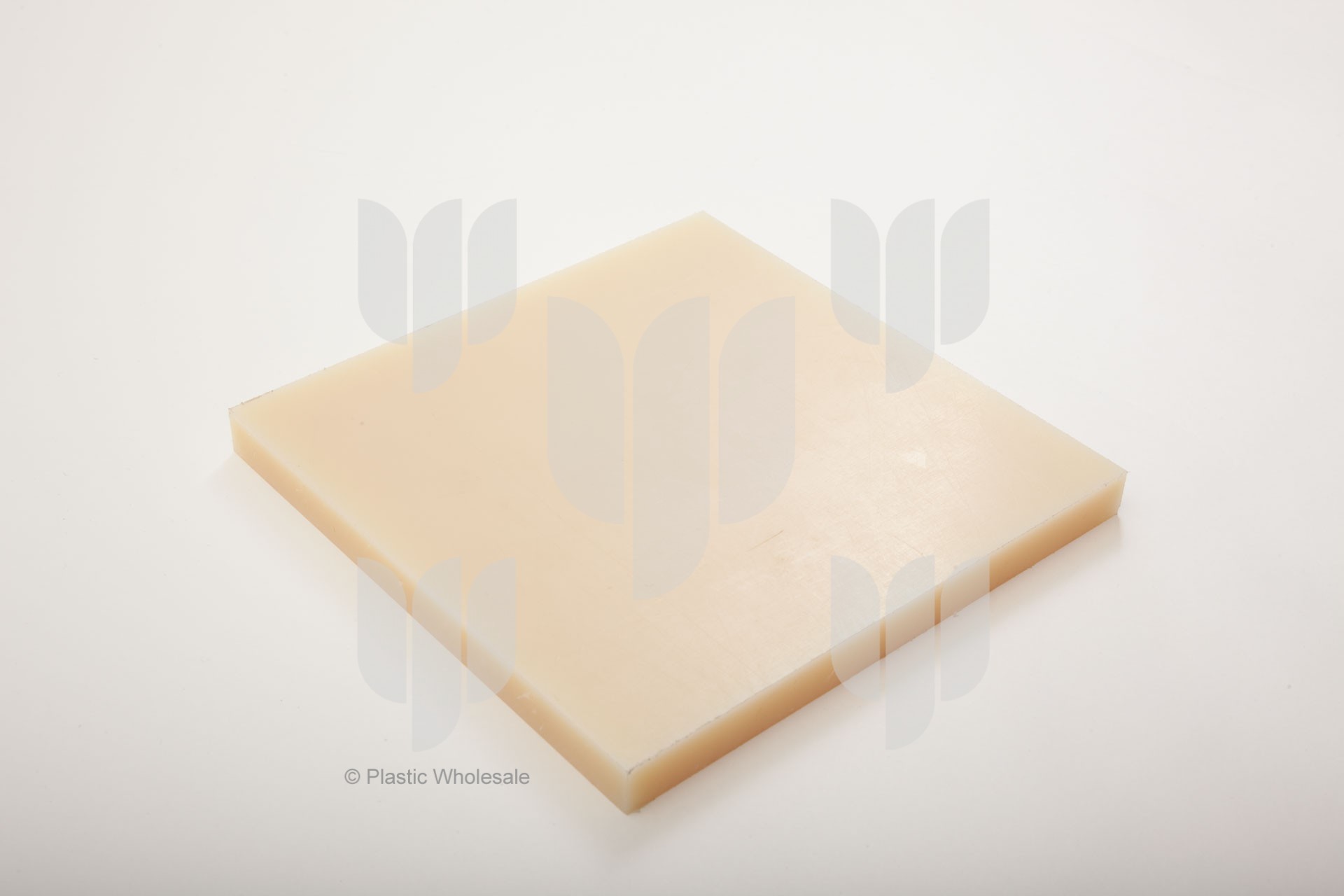

About Nylon

Nylon is a strong, silky-textured thermoplastic and the generic designation for the polyamide family of synthetic polymers.

It is a versatile material with excellent abrasion resistance and a low coefficient of friction, making it an ideal substitute for a wide range of materials, from rubber to steel.

Relatively easy to fabricate and machine, nylon is one of the world’s most commonly used polymers and can be processed by injection moulding, extrusion and casting.

Download datasheet (147Kb)

Download datasheet (147Kb)

History

1935 – Nylon is developed from strong polyamide fibre and patented by DuPont

1938 – First used commercially in a nylon-bristled toothbrush

1940 – Nylon stockings go on sale to the public, with DuPont selling 64 million pairs in the first year

1942 – Nylon is put to use in World War II as a replacement for hemp and Asian silk. It is used for tents, parachutes, ropes and tyres

1969– The first astronauts on the moon wear space suits containing nylon fibres, with Neil Armstrong planting a flag made of nylon

Applications

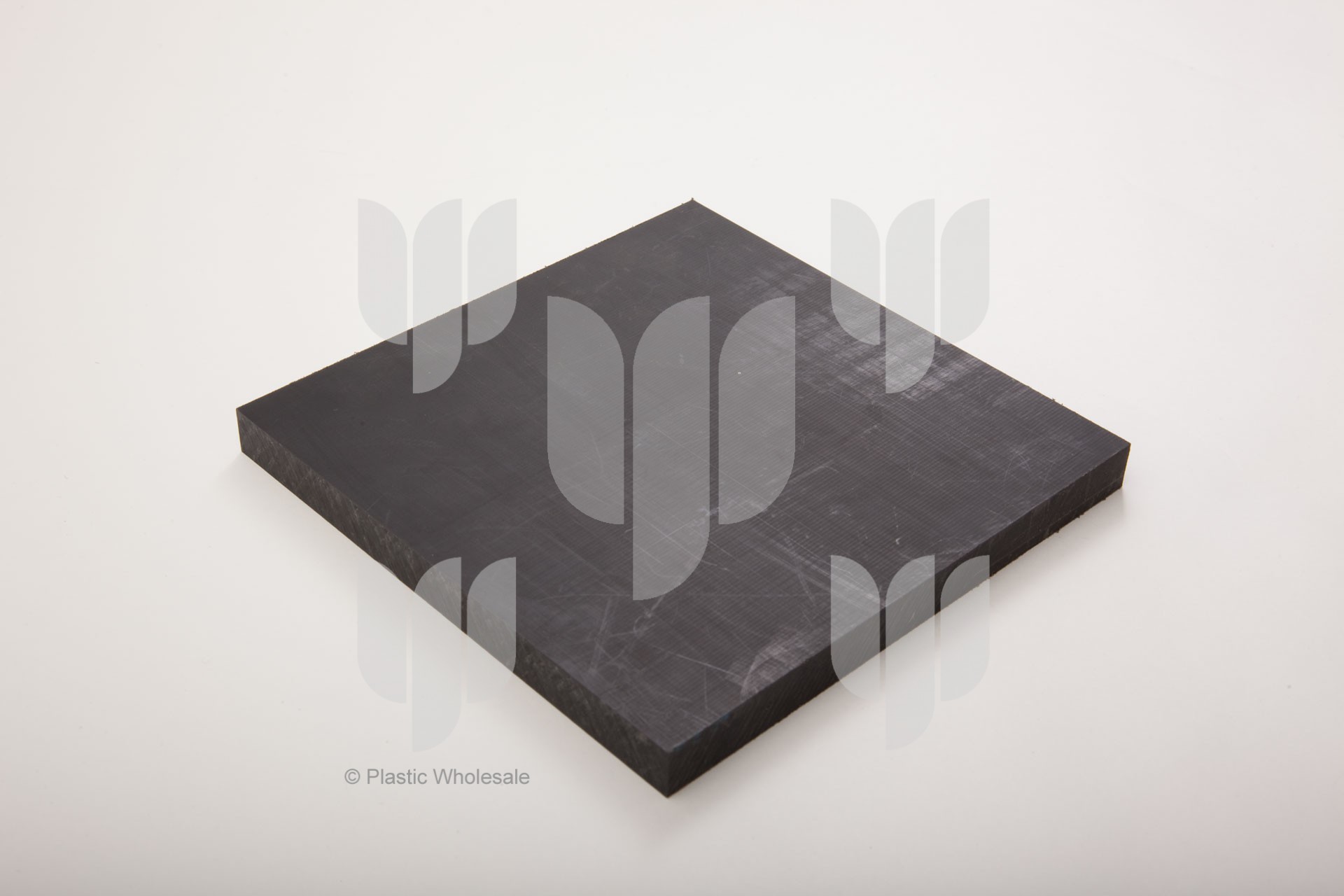

Known as one of the strongest plastics on the market and sold in several grades, nylon is used in transportation for load-bearing where UHMW is of insufficient strength. It is also used for the following:

- Wear strips: Like UHMW, nylon is used for wear strips and as roll bearings for conveyor systems. Standard nylon is less oily than UHMW however, and therefore not suitable for sliding material across its surface, although oil filled nylon is used where friction exists and higher strength is required

- Road construction: Nylon rods can be used as rollers for transporting heavy items; such as rolling a very large stormwater pipe underneath a multi-lane road

- Composites: Nylon is used as the matrix material in combination with reinforcing material such as carbon fibre and glass. Its high heat resistance makes it a popular substitute for metal for components such as intake manifolds

- Mechanical parts: Solid nylon is used for low- to medium-stress mechanical parts previously cast in metal, such as machine screws and gears

- Fibres: Nylon fibres are used for a wide variety of applications including carpets, surgical sutures, musical strings, rope, bridal veils, netting and women’s hosiery

Key Properties

General

Density relative to water (=1), 1.15

Water absorption (24 hrs), 1.20%

Thermal

Continuous Service Temperature, 90°C (176°F)

Melting point, 215°C (419°F)

Mechanical

Tensile Modulus of Elasticity, 3600 MPa

Elongation at Yield, 5%

Elongation at Break, 25%

Impact Strength, Notched Izod @ 23°C, 7.0 kJ/m2 (3.32 ft-lbs/in2)

![]() Download datasheet (147Kb)

Download datasheet (147Kb)