About Polypropylene

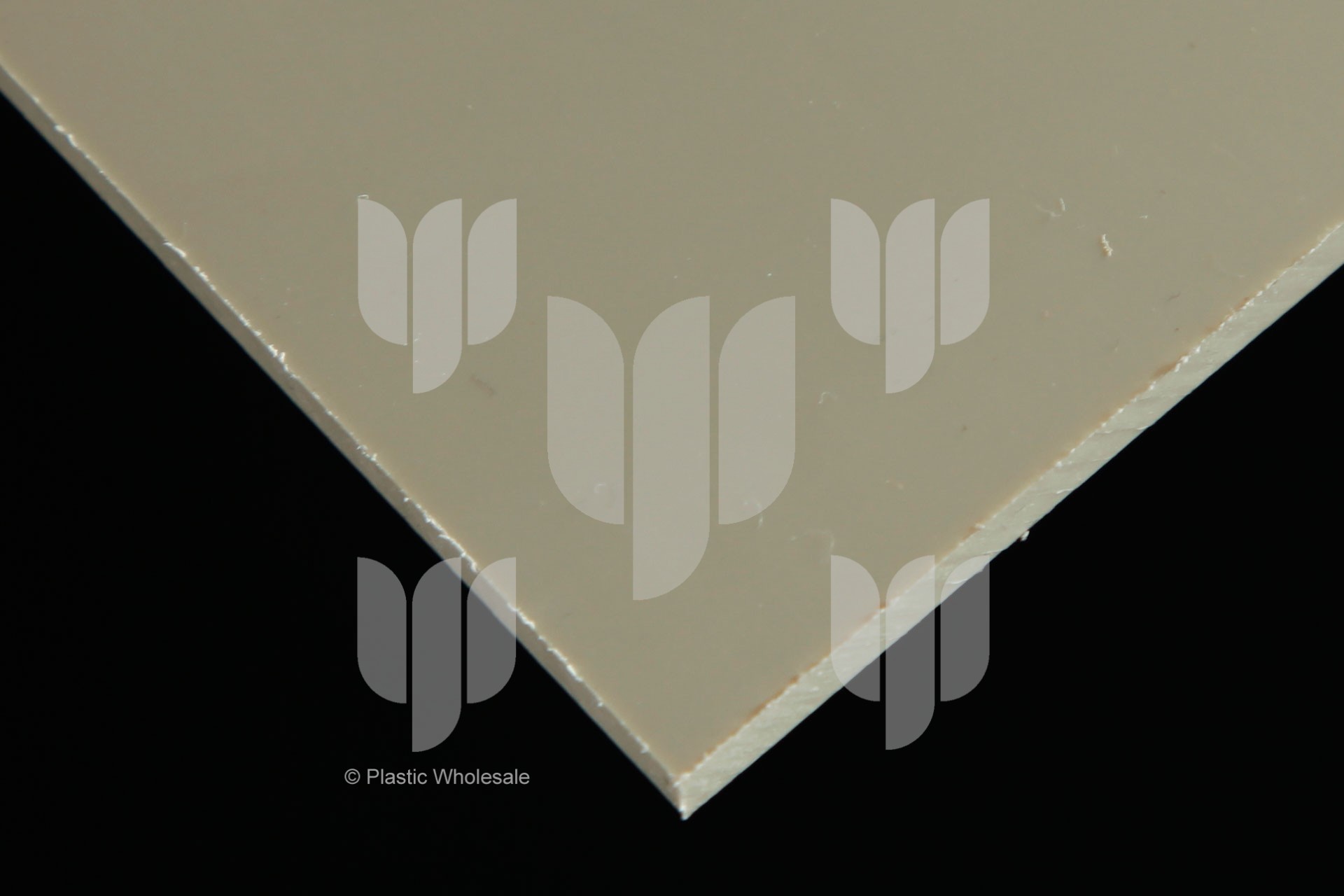

Polypropylene is a flexible, rugged thermoplastic used for a wide variety of applications, from plastic currency to food containers and industrial moulds.

It provides good fatigue properties and exceptional resistance to chemicals, including acids and solvents. These same chemical resistant properties make polypropylene difficult to glue because it is resistant to the chemicals in glue.

It has a high melting point compared to many other plastics, and can be used both as a structural plastic and as a fibre.

It is most commonly processed by injection and extrusion, to be made into products such as house wares, containers and automotive parts.

Download datasheet (142Kb)

Download datasheet (142Kb)

History

1954 – Polypropylene is successfully polymerised by Giulio Natta and Karl Rehn.

1957 – Italian firm Montecatini commences large-scale production of commercial-grade isotactic polypropylene.

2008 – The global market for polypropylene has reached a volume of 4.1 million tonnes, with a turnover of around $US64 billion.

Applications

Polypropylene finds a wide variety of uses, due in large part to the ability to tailor it to various grades during manufacture. These include:

- Food Containers: Polypropylene is often used for food containers as it is dishwasher safe and has a high melting point, making it less prone to warping in hot water.

- Pipes: Polypropylene is chosen for piping systems for its strength, rigidity and resistance to corrosion and chemical leaching, and ability to be joined through heat fusion rather than gluing

- Hinges: Most plastic living hinges, such as those on flip-top bottles and Tic Tacs boxes, are made of polypropylene, which offers superior fatigue resistance

- Capacitors: Polypropylene is an extremely efficient dielectric material which does not corrode or become brittle, and provides excellent thermal insulation as well as a low dissipation factor

- Medical and Laboratory: Many plastic items are made of polypropylene for its chemical resistance and ability to withstand the heat in an equipment steriliser

- Synthetic Carpet: Polypropylene can be dyed easily and is extremely hard-wearing and water resistant, making it an ideal substitute for nylon as outdoor carpeting for swimming pools and recreational areas

Key Properties

General

Density relative to water (=1), 0.92

Water absorption (24 hrs), 0.10%

Thermal

Continuous Service Temperature, 100°C (212°F)

Melting point, 160°C (320°F)

Mechanical

Tensile Modulus of Elasticity, 1350

Tensile Strength at Break, 34 Mpa

Elongation at Break, 14%

Impact Strength, Notched Izod @ 23°C, 1.9 ft-lbs/in

![]() Download datasheet (142Kb)

Download datasheet (142Kb)