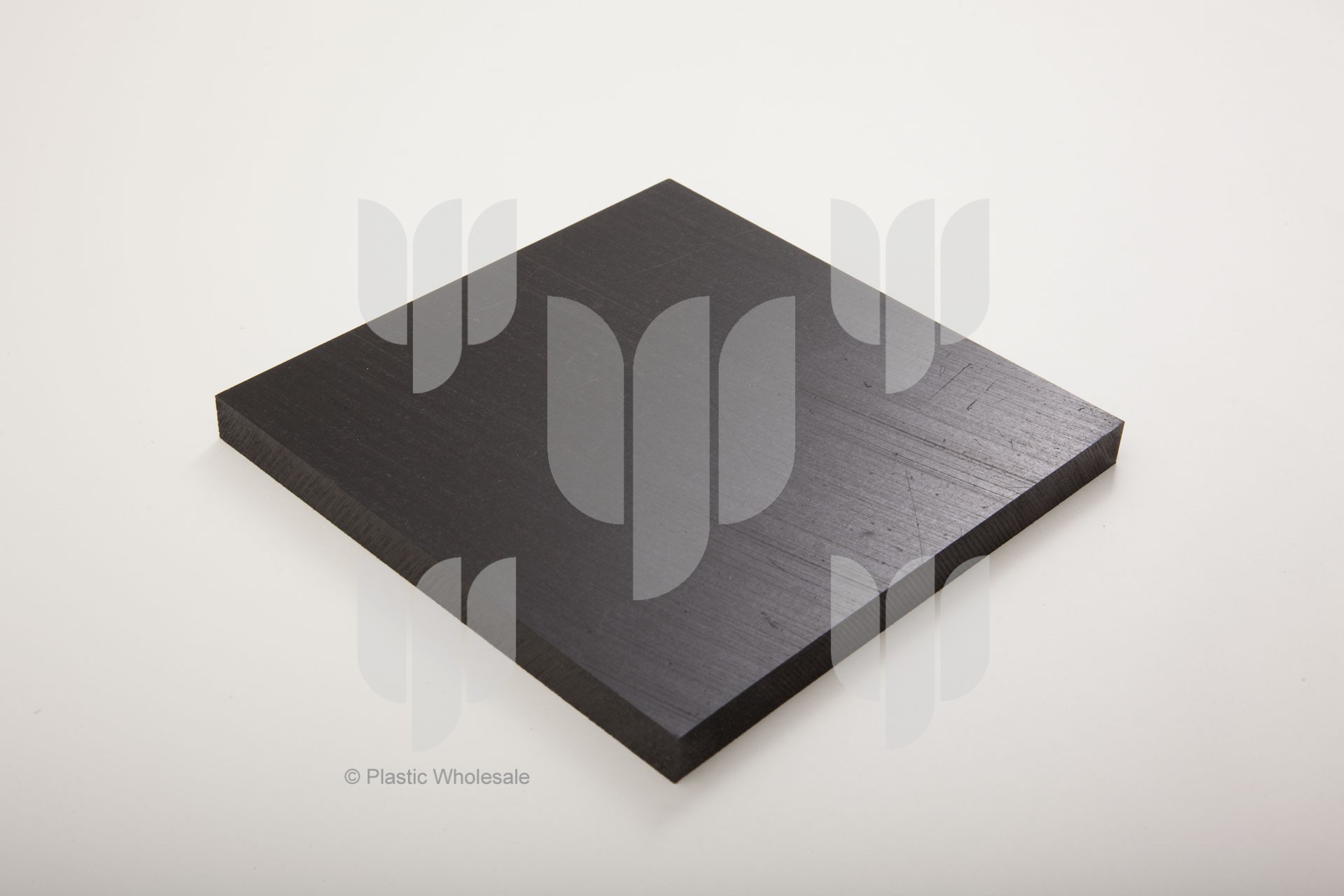

About Ultra High Molecular Weight Polyethylene

Ultra High Molecular Weight Polyethylene (UHMW, UHMWPE) is a thermoplastic characterised by long molecular chains and high resistance to cut, wear and chemical corrosion.

Its extremely long molecular chains – with molecular weight ranging between 3.1 and 5.67 million – give it the ability to withstand high impact and extreme load.

Used where strength and durability are especially important, its applications include high-stress machine parts and artificial joints. Its’ very low coefficient of friction is comparable to that of Teflon®.

Download datasheet (160Kb)

Download datasheet (160Kb)

History

1898 – Polyethylene is discovered by accident by German chemist Hans von Pechmann while he is heating diazomethane

1950s – UHMW is commercialised by German chemical company Ruhr Chemie AG, now known as Sanofi-Aventis

1960s – Becomes the preferred material for total joint replacement in spinal and orthopaedic implants

1970s – UHMW fibres are commercialised by Dutch company DSM. They would be used in defence, ballistics and medicine

1998 – Highly crosslinked UHMW is introduced, becoming the material of choice for total hip replacements.

Applications

The high strength, impact resistance and durability of UHMW make it suitable for many different industrial applications. These include:

- Conveyor systems: UHMW is used as roll bearings and corner tracks in conveyor systems such as in mining, saw mills and food processing plants. It is especially useful in food conveyor systems due to its non-toxic, tasteless and odourless properties

- Wear pads: UHMW is extremely useful for high impact and high friction applications, and frequently used as wall linings in quarries and for other mining applications. It is also used for the protection of metal-on-metal impact in heavy industrial applications, and for turntable protection on semi-trailers

- Easy sliding: UHMW is used to line dump trucks so that the material being dumped clears efficiently. Without UHMW, dump trucks frequently return with much of the original material still in the tray, which is referred to as the “return load”. This return load reduces the efficiency of the dump cycle which in turn increases the time that these trucks require to complete the task at hand. UHMW also protects the dump truck bin metal from impact and friction damage. Additionally, UHMW is used to slide heavy industrial components into place, such as large storm water pipes under roads and highways

- Mechanical engineering: UHMW is used for a wide variety of machine components, including bottle handling machine parts, gears, bearings and moving parts in weaving machines

- Medicine: The durability and chemical safety of UHMW make it the material of choice for hip and knee replacements

Key Properties

General

Density relative to water (=1), 0.94

Water absorption (24 hrs), less than 0.01%

Thermal

Continuous Service Temperature, 80°C (176°F)

Melting point, 148°C (298°F)

Mechanical

Tensile Modulus of Elasticity, ≥700 MPa

Elongation at Break, >50%

Yield Stress, ≥17 MPa

Impact Strength, Notched Izod @ 23°C, No break

![]() Download datasheet (160Kb)

Download datasheet (160Kb)