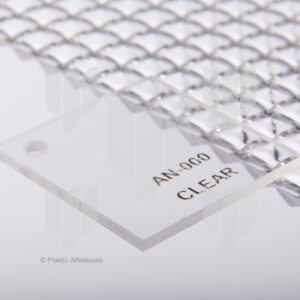

About Acrylic Prismatic Light Diffuser Material

Prismatic light diffuser material comes in 2 main thicknesses, approximately 3mm and 4.5mm. The 3mm material, referred to as P12 or K12 has a prism depth of approximately 1.9mm while 4.5mm material, referred to as P15 or K15 has a prism depth of approximately 2.3mm.

Both the P12/K12 and P15/K15 provide good light control in situations where there is considerable glare. The critical issue for prismatic is the span over which the material can safely be hung. In the case of 3mm material, the ideal maximum span is 600mm on the shortest side or less, whereas for the 4.5mm material, the ideal maximum span is 800mm or less, but with proper support in the middle and fixings on the edges, this can be extended.

While it is an excellent diffuser of light, prismatic tends to get broken easily if not treated with care. This is because the very pattern that is rolled into the material as it is extruded; in-fact makes the material thinner than it would otherwise be, and therefore more brittle. Where larger panels of prismatic are being used, it is important that the appropriate frame, drilling or adhesive is used to mitigate the chance of the material popping out in variable weather.

More generically, acrylic, also known as Plexiglas®, is a transparent thermoplastic that is often chosen as a light, durable and cost-effective replacement for glass and is 17 times stronger than glass.

Download datasheet (154Kb)

Download datasheet (154Kb)

History

1893 – Acrylic acid is synthesised by French chemist Charles Moureau.

1928 – Acrylic glass, known chemically as PMMA (polymerised methyl methacrylate), is first developed in the laboratory.

1933 – PMMA is brought to market as Plexiglas® by Rohm and Haas.

1936 – The first commercially viable acrylic safety glass is manufactured. It would be used in World War II for windshields, canopies and periscopes. The uses of acrylic would expand significantly throughout the 1950s & 60s.

Applications

Acrylic is one of the world’s most popular plastics due to a favourable combination of properties, which include being chemically safe, less than half the weight of glass, a better thermal insulator and more transparent, allowing 92% of visible light to pass through unabsorbed.

It is used for the following:

- Glass Substitute: Glaziers use acrylic as an affordable alternative to glass

- Signage: Sign-writers use it for large signs, fixing clear or coloured vinyl with digitally printed images over the sheet surface

- Fencing: Acrylic is an affordable choice for pool fencing, animal enclosures, vegetable gardens, and home decking

- Aquariums: Acrylic is a popular choice for aquariums, as it is shatter resistant and easily moulded into any number of shapes

Acrylic is also used for skylights, protective covers for computers, briefcases, jewellery displays, book stands and brochure holders, lighting fixtures, motorbike helmet visors, safety shields at sporting venues, modern furniture, and many other applications.

Key Properties of Extruded Acrylic Prismatic Light Diffuser Material

Type K12, K15

Thickness 3mm, 4.4mm

Prism Pattern 5mm, 9.5mm

Pattern 45 Degree Axis, Square to Sheet

Direction of Prisms Female, Female

Depth of Prism 1.9mm, 2.3mm

Unified Glare Rating 21, 17

Light Output Ratio 73%, 81%

Flammability Rating UL94 HB, UL94 HB

Maximum Span of Shortest Side 600mm, 800mm & up to 1000mm with proper fixings

Key Properties

General

Density relative to water (=1), 1.219

Water absorption (24 hrs), 0.03%

Thermal

Continuous Service Temperature, 85°C (185°F)

Melting point, 160°C (320°F)

Mechanical

Tensile Strength at Break, 70 Mpa

Elongation at Break, 4%

Flexural Strength, 114 Mpa

Impact Strength, Notched Izod @ 23°C, 0.21 J/cm (0.4 ft-lbs/in)

![]() Download datasheet (154Kb)

Download datasheet (154Kb)