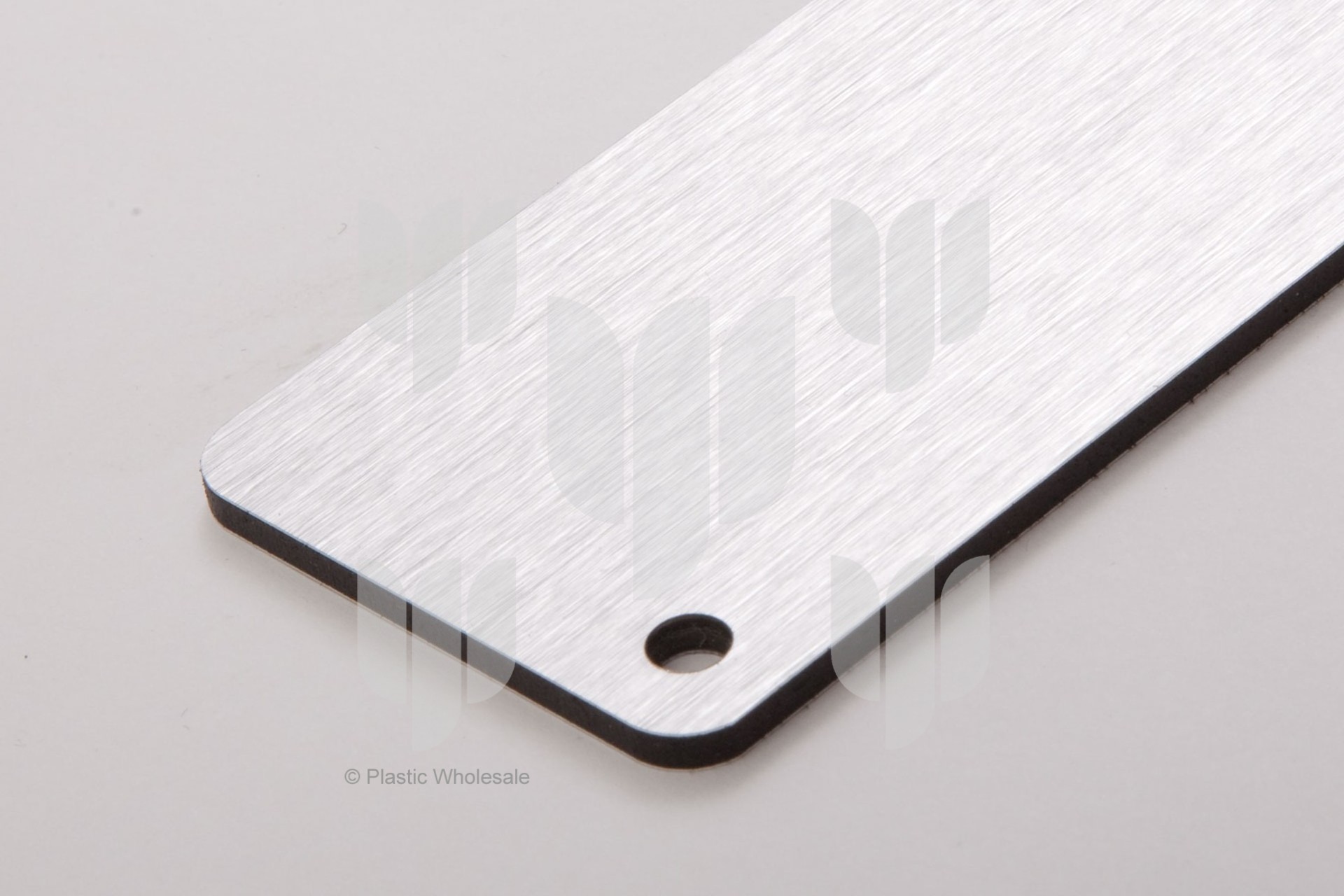

About Aluminium Composite Material (ACM)

Aluminium Composite Material (ACM) is a composite panel made by bonding two thin layers of 0.13mm – 0.3mm thick aluminium to a low-density polyethylene core.

It is very strong and rigid despite its light weight, and is frequently used as signage, insulation and as external cladding for buildings.

The aluminium provides a surface that can be coated with PVDF or polyester paint, producing almost any kind of colour or pattern, including metallic and non-metallic finishes, and imitation of other materials, such as wood or marble.

Download datasheet (164Kb)

Download datasheet (164Kb)

History

1960s – ACM is first developed, along with the first advanced architectural adhesive resins. One of its first applications is cladding for buildings

1970s – ACM gains widespread commercial availability as an architectural product

1990s – ACM is developed as a product designed specifically for the display and signage industries

Applications

In addition to high strength, rigidity and impact resistance, ACM provides an extremely flat and smooth surface that is weatherproof and resistant to corrosion and pollution, making it suitable for a range of indoor and outdoor uses. These include:

- Signage – ACM is used as an alternative to acrylic for signs as it is much stronger per unit area, ensuring that the signs do not sag or oscillate at the edges. This makes it a good choice for advertising signs, trade stands and point of sale displays

- Building – ACM is used as external building cladding (facades). It is also used internally for partitioning, wall linings and suspended ceilings. A wide selection of colours and styles make ACM panelling popular for shopfitting and shop fronts

- Cabinet Making – ACM is used to make splash backs for kitchens and other wet areas

- Manufacturing – ACM is increasingly being used in manufacturing as a substitute for steel. Its strength, rigidity and relatively light weight coupled with its relatively cheap price make it ideal for use as non-load bearing panels

Key Properties

General

Density relative to water (=1), 1.29

Aluminium Thickness, 0.21mm

Aluminium Thickness Deviation, ±0.02mm

Horizontal Flatness, 5mm

Coating Thickness, ≥ 16μm

Surface Hardness, 2H

Thermal

Continuous Service Temperature, 80°C (176°F)

Minimum Service Temperature, -50°C (-58°F)

Thermal Expansion (100°C difference), 2.4mm/m

Heat Transition Coefficient, 5.6 W/m2K

Thermal Resistance, 0.007 m2K/W

Mechanical

Proof Stress (0.2%), >100 N/mm2

Tensile Modulus of Elasticity, 70000 N/mm2

Tensile Strength at Break (of Aluminium), >144 N/mm2

Rigidity (μ = 0.3), 0.15 kNcm2/m

Elongation (A50), ≥ 2 %

Acoustic

Sound Absorption (αs factor), 0.05

Sound Loss (d factor), 0.007

![]() Download datasheet (164Kb)

Download datasheet (164Kb)