About Acrylic

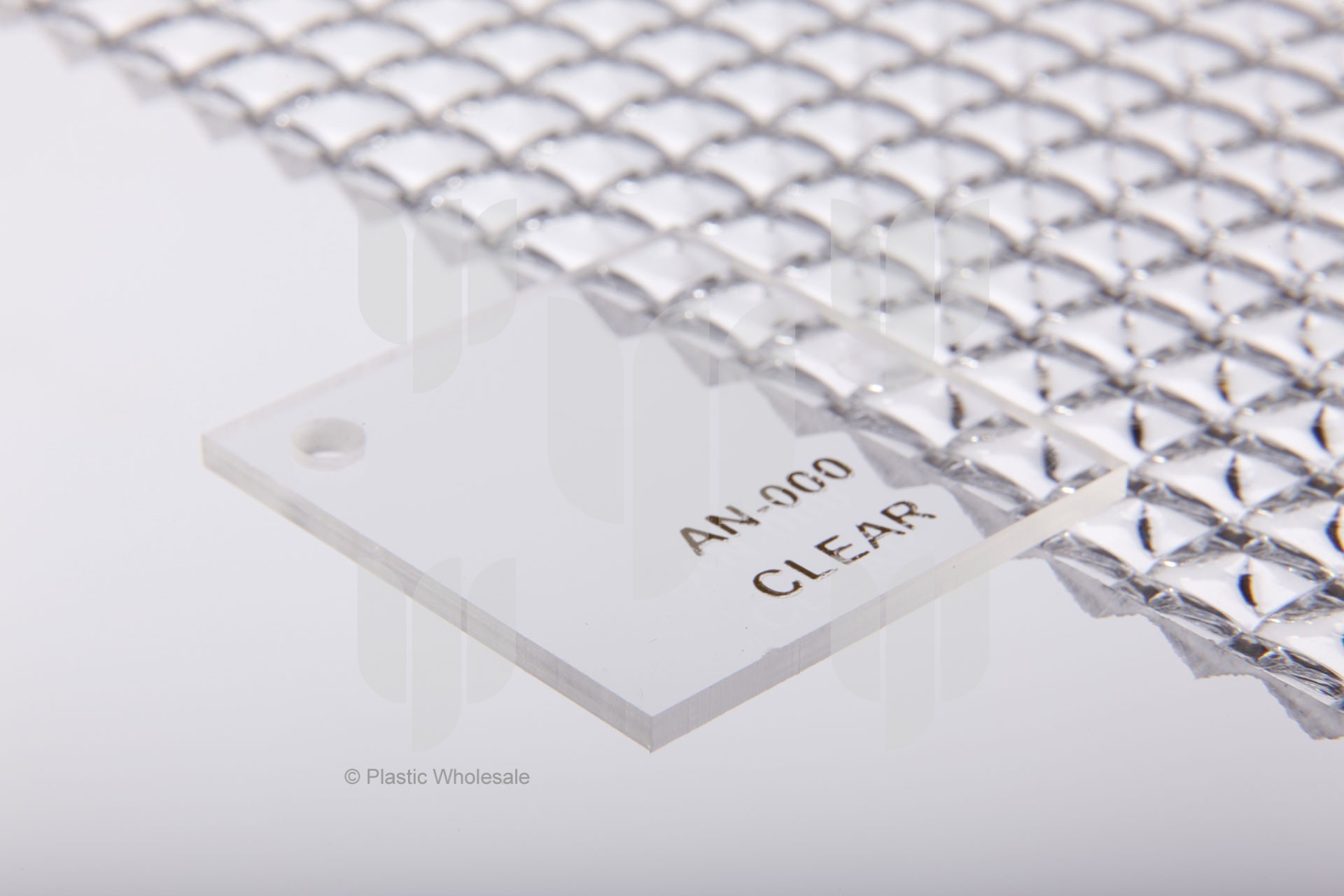

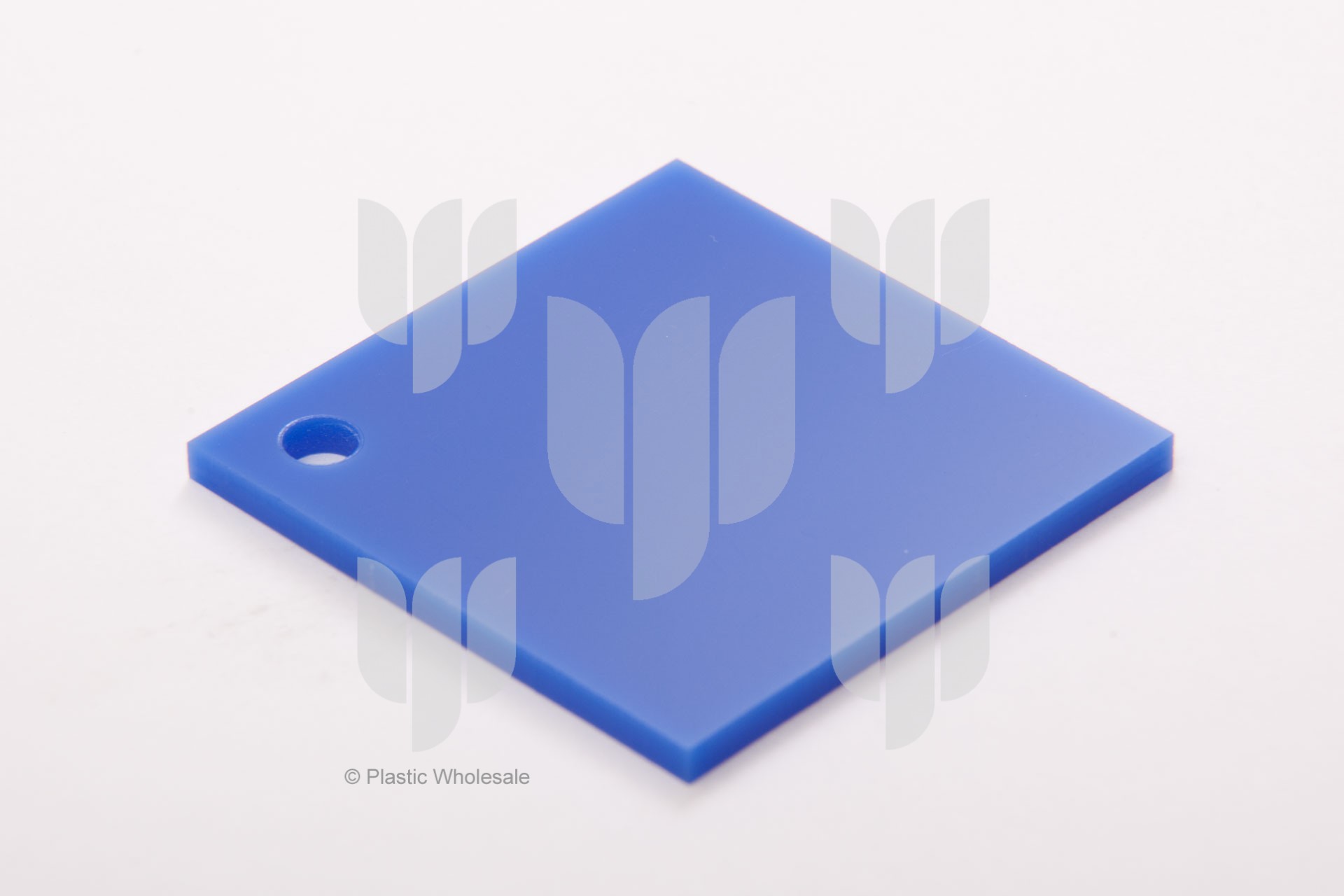

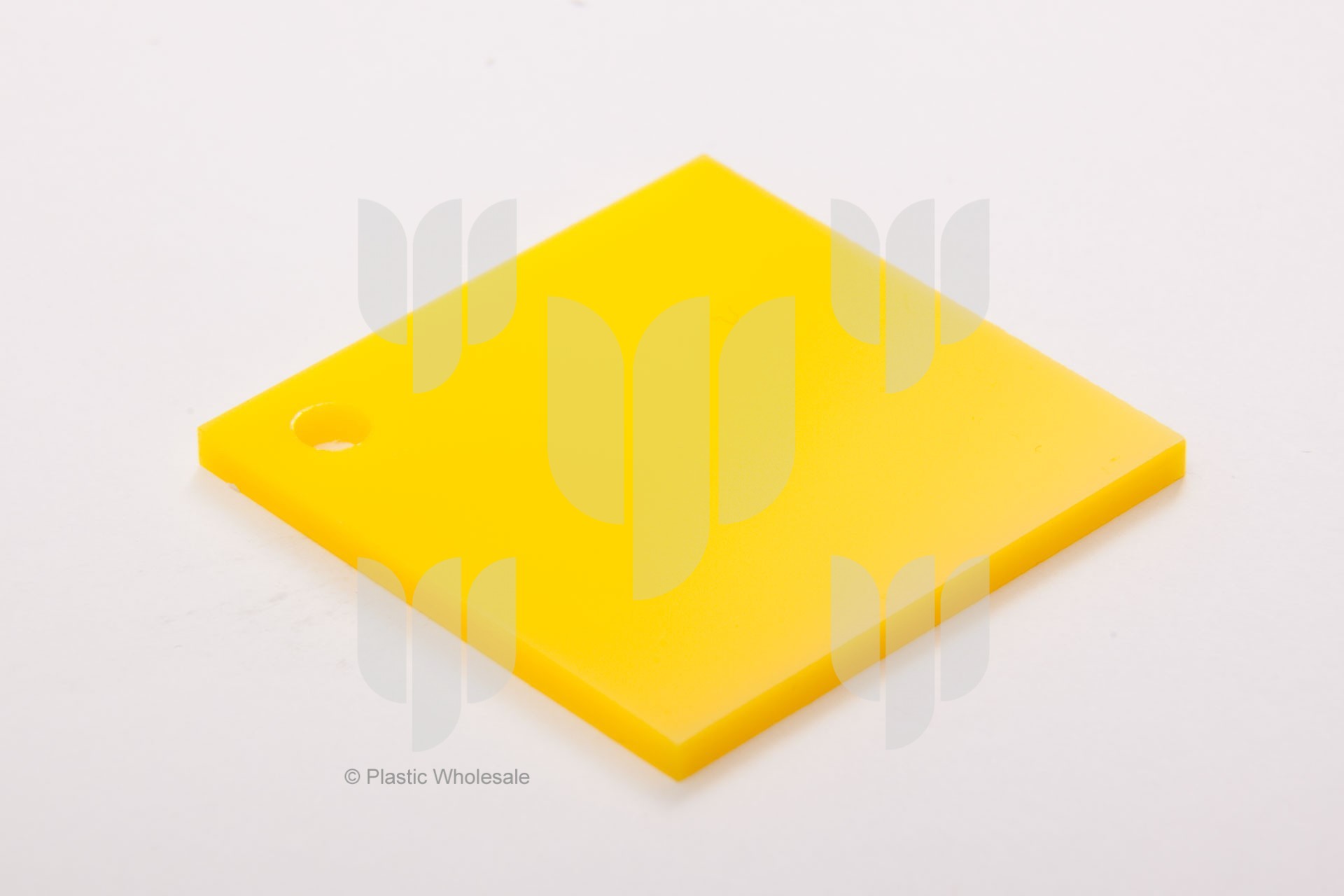

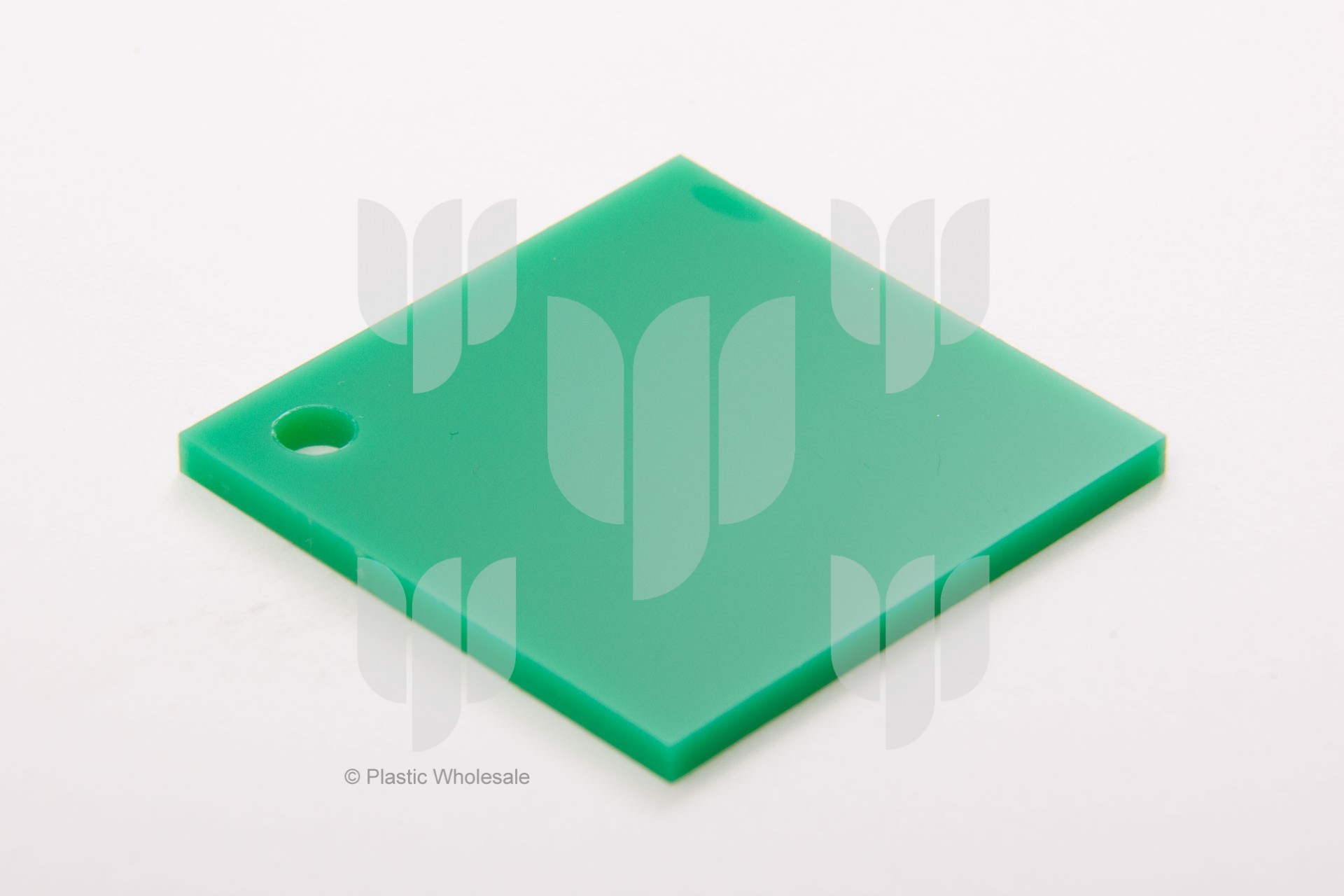

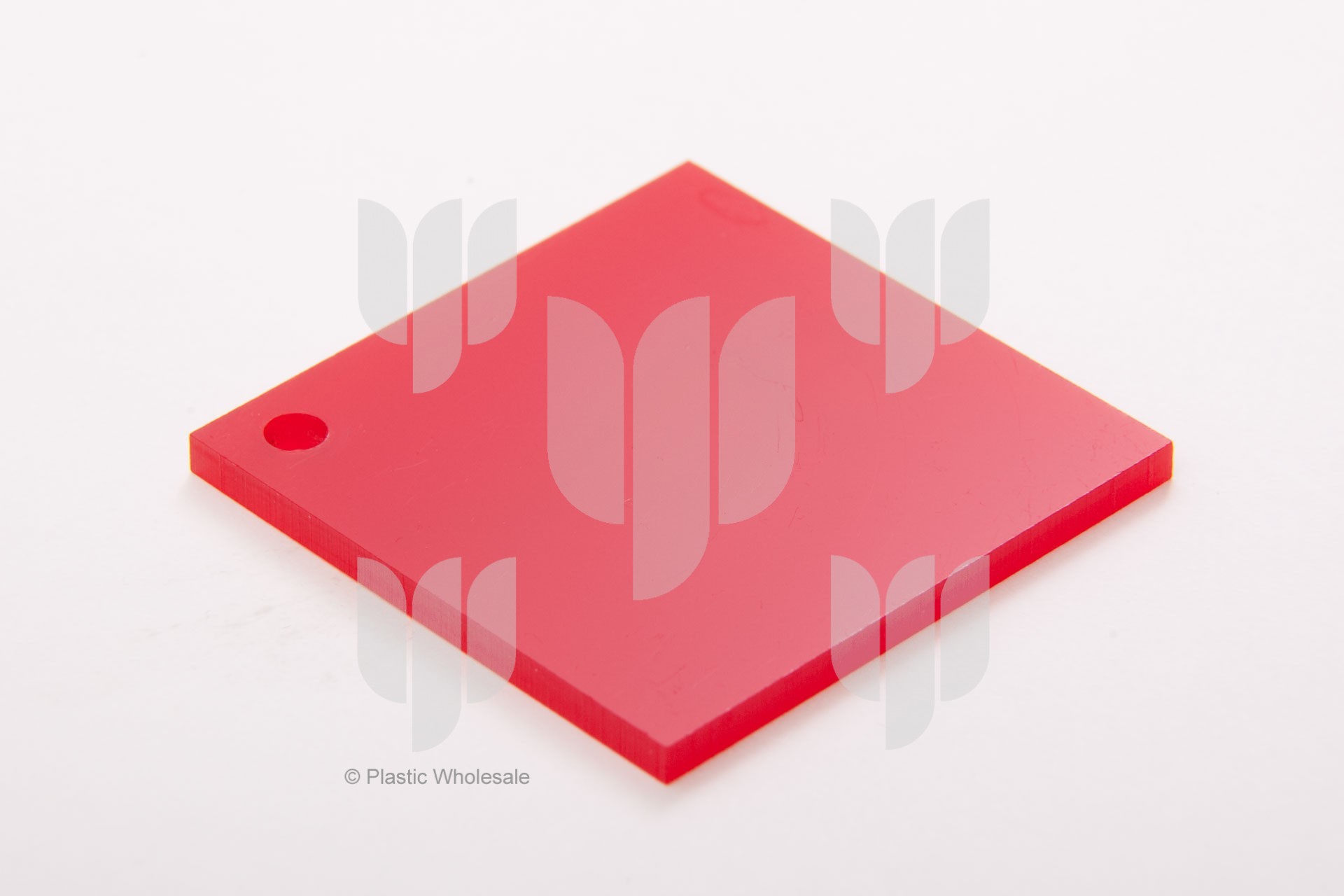

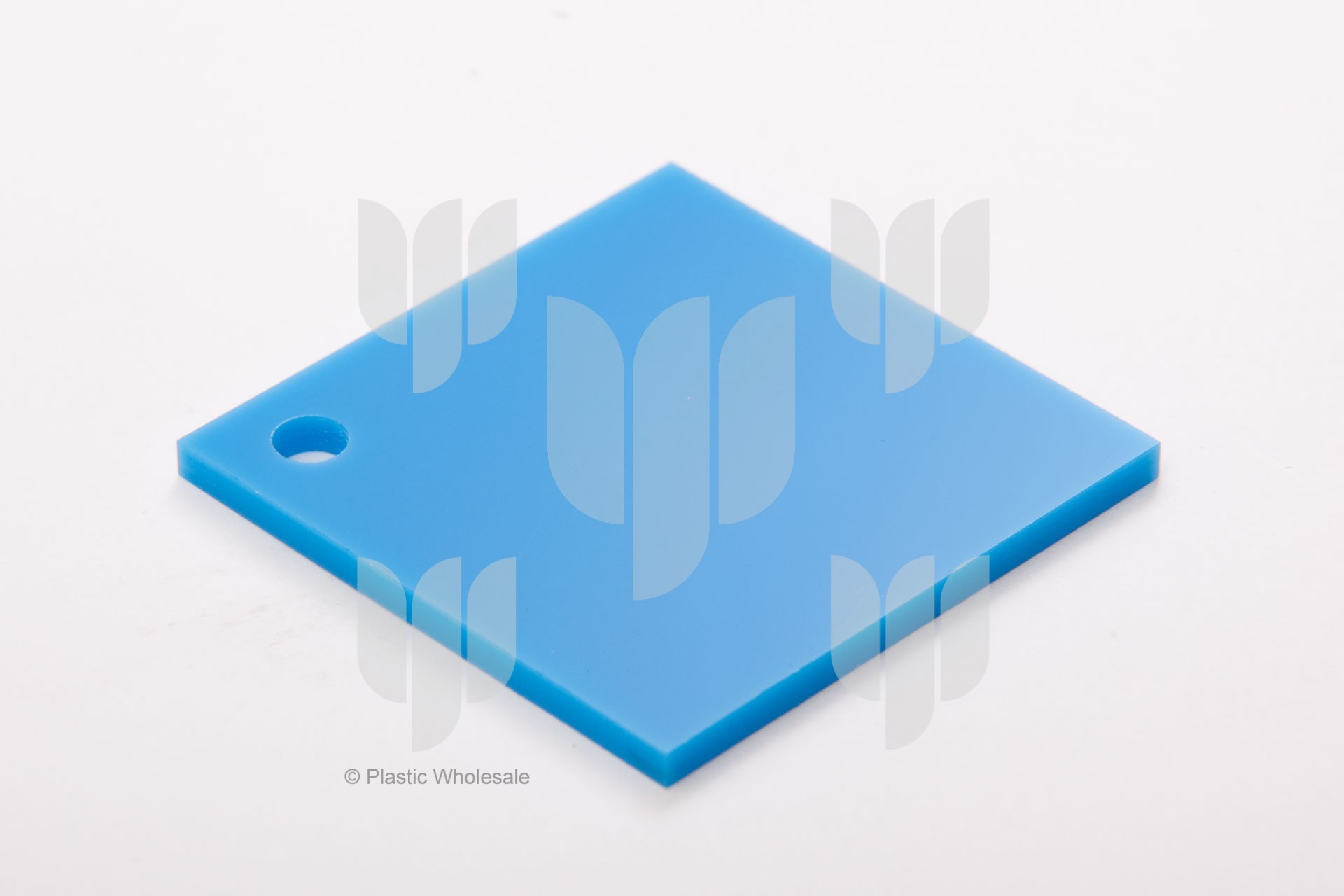

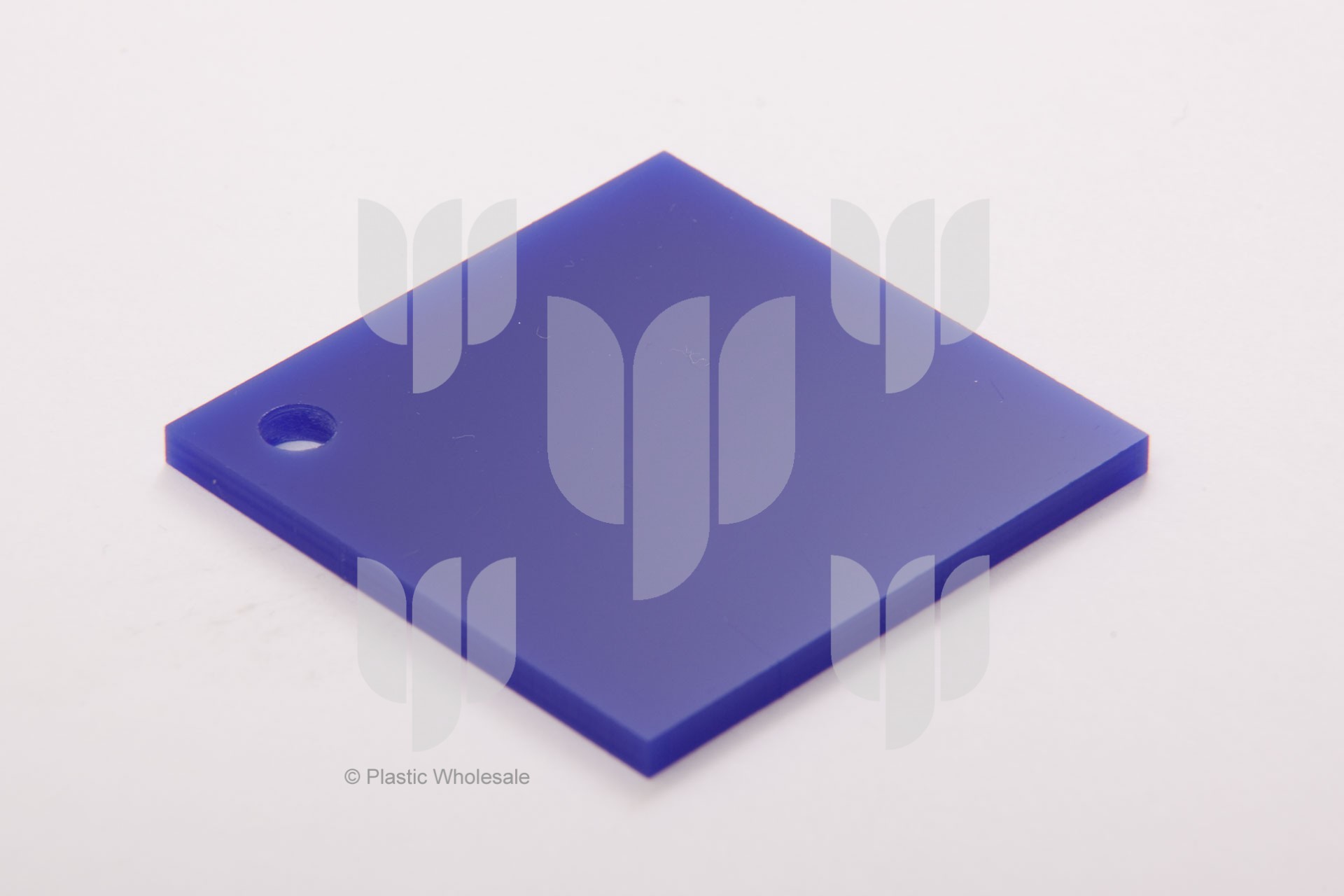

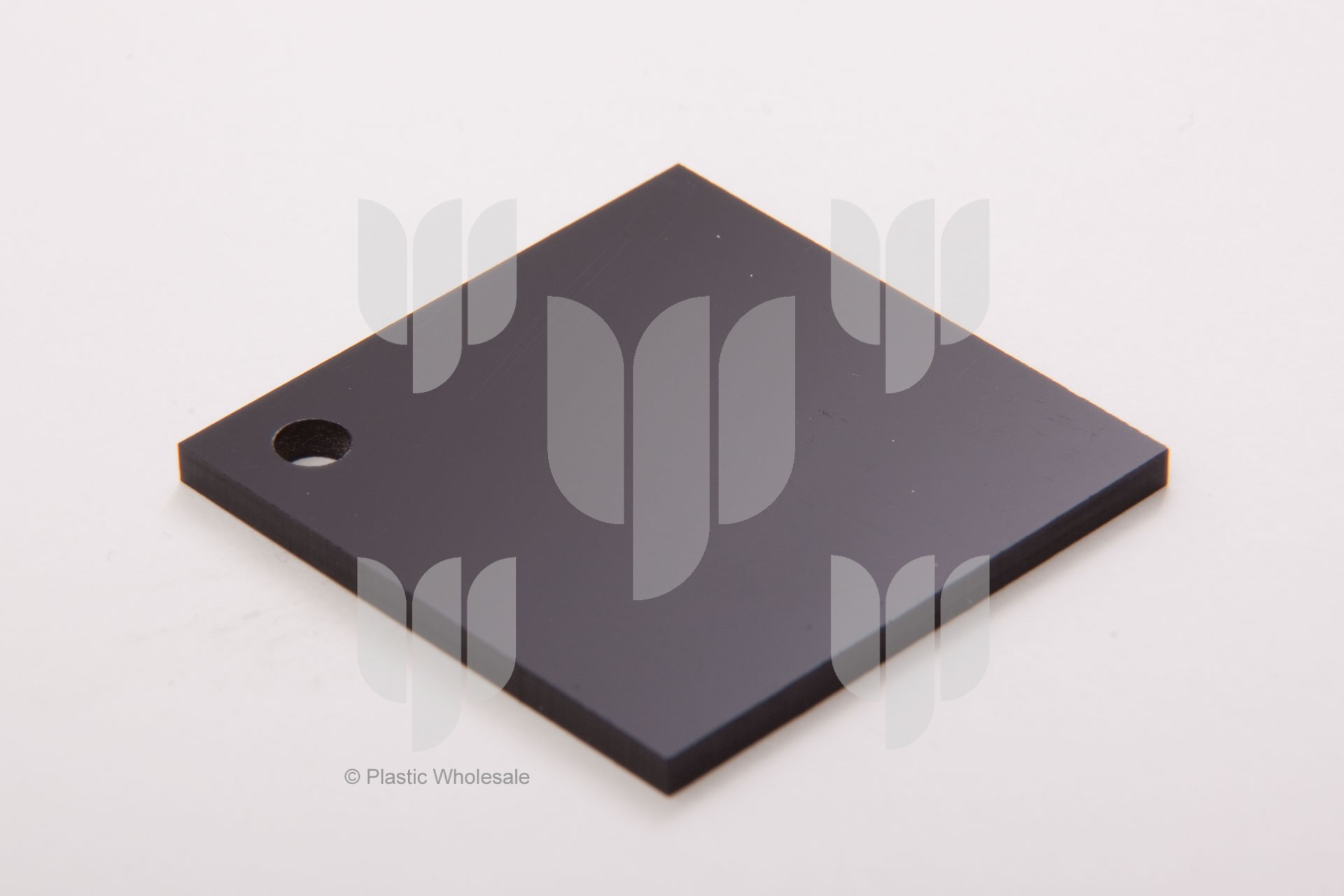

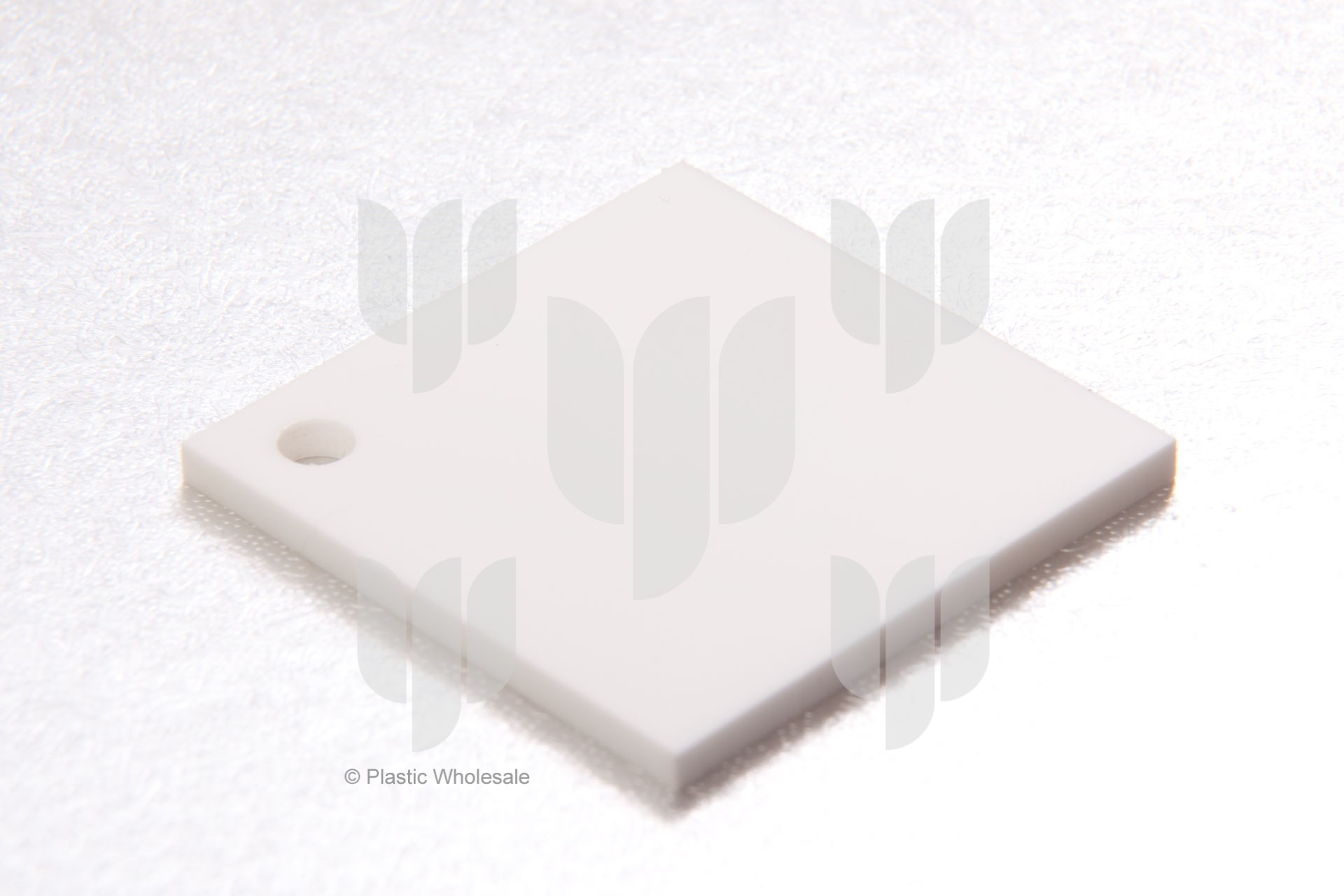

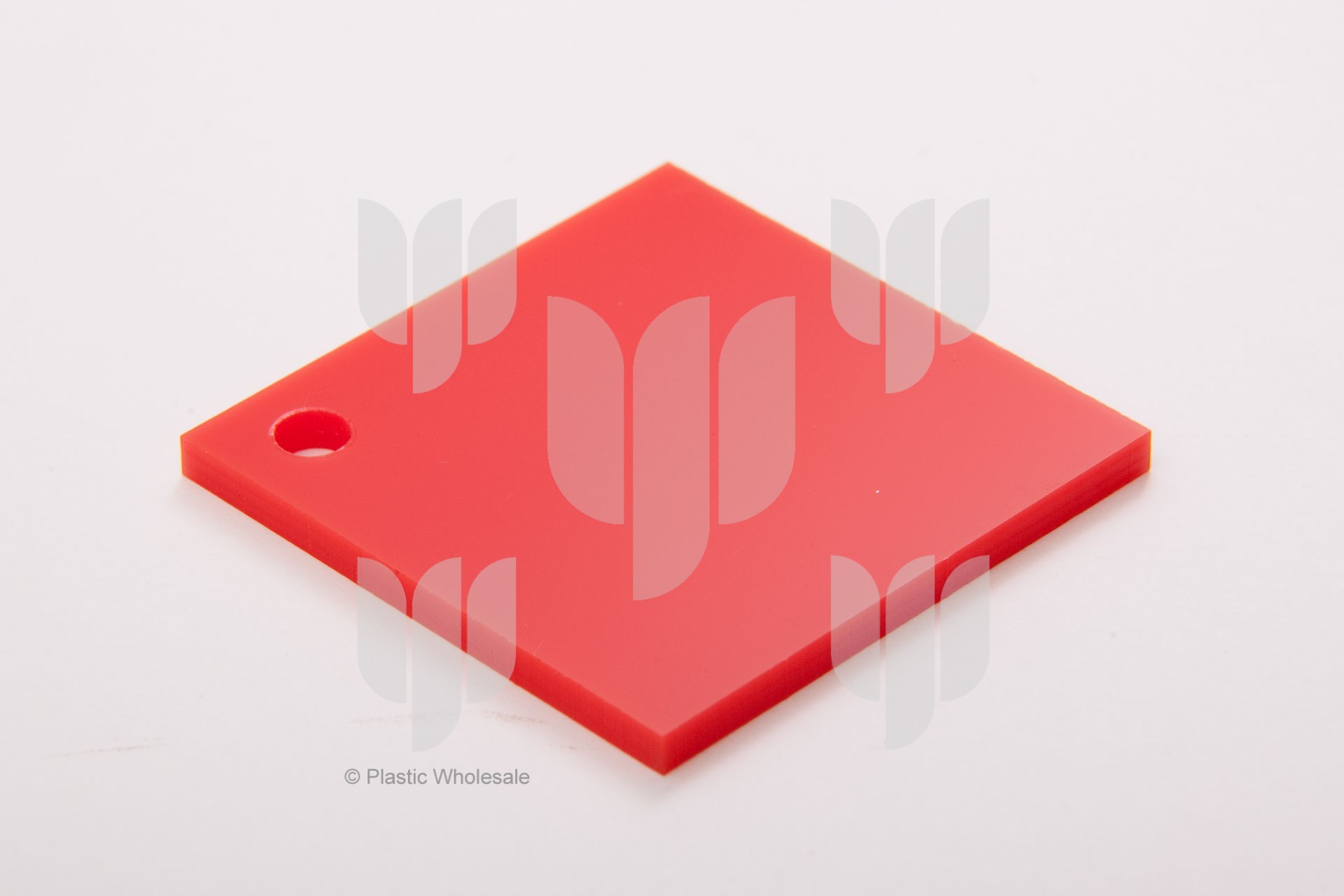

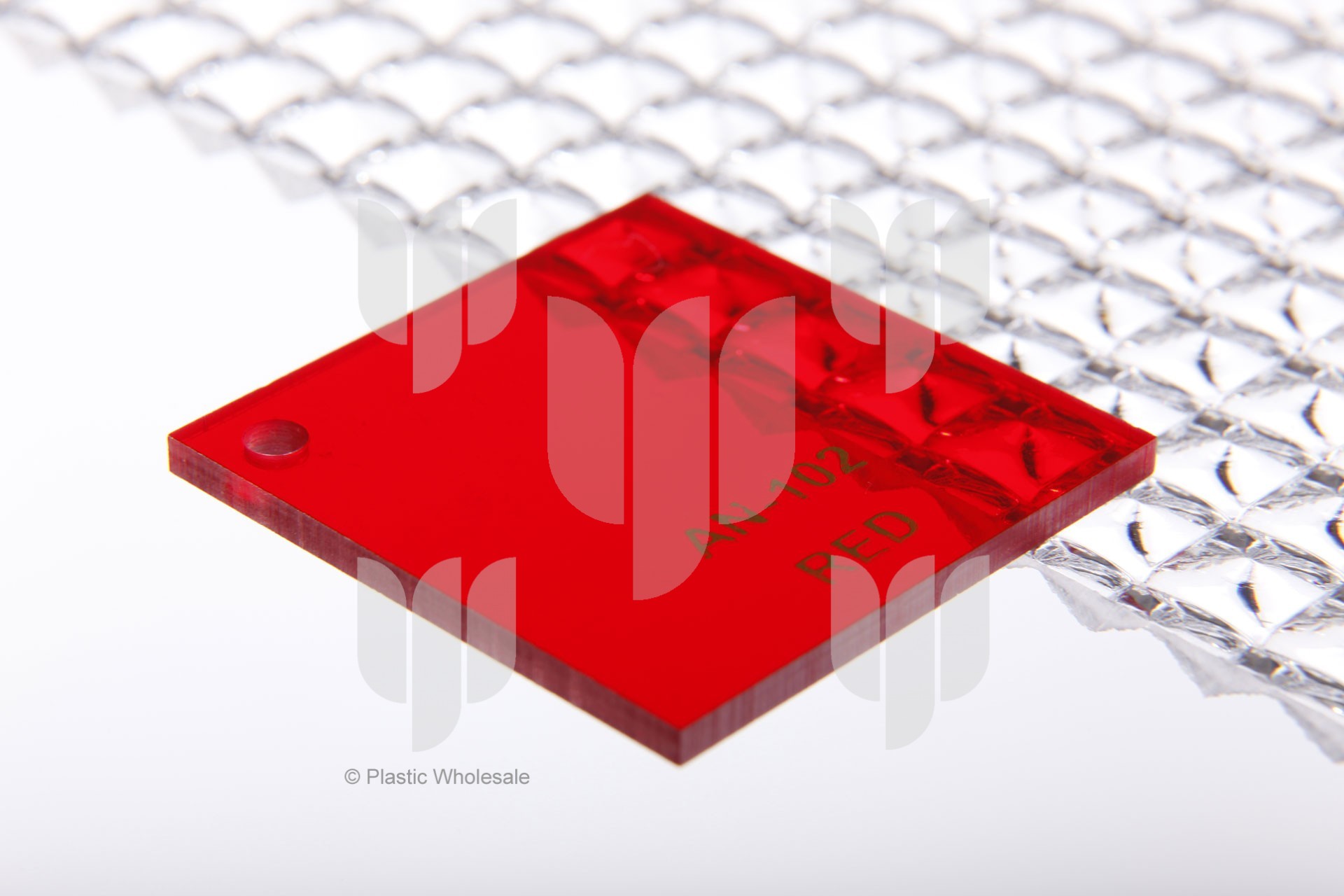

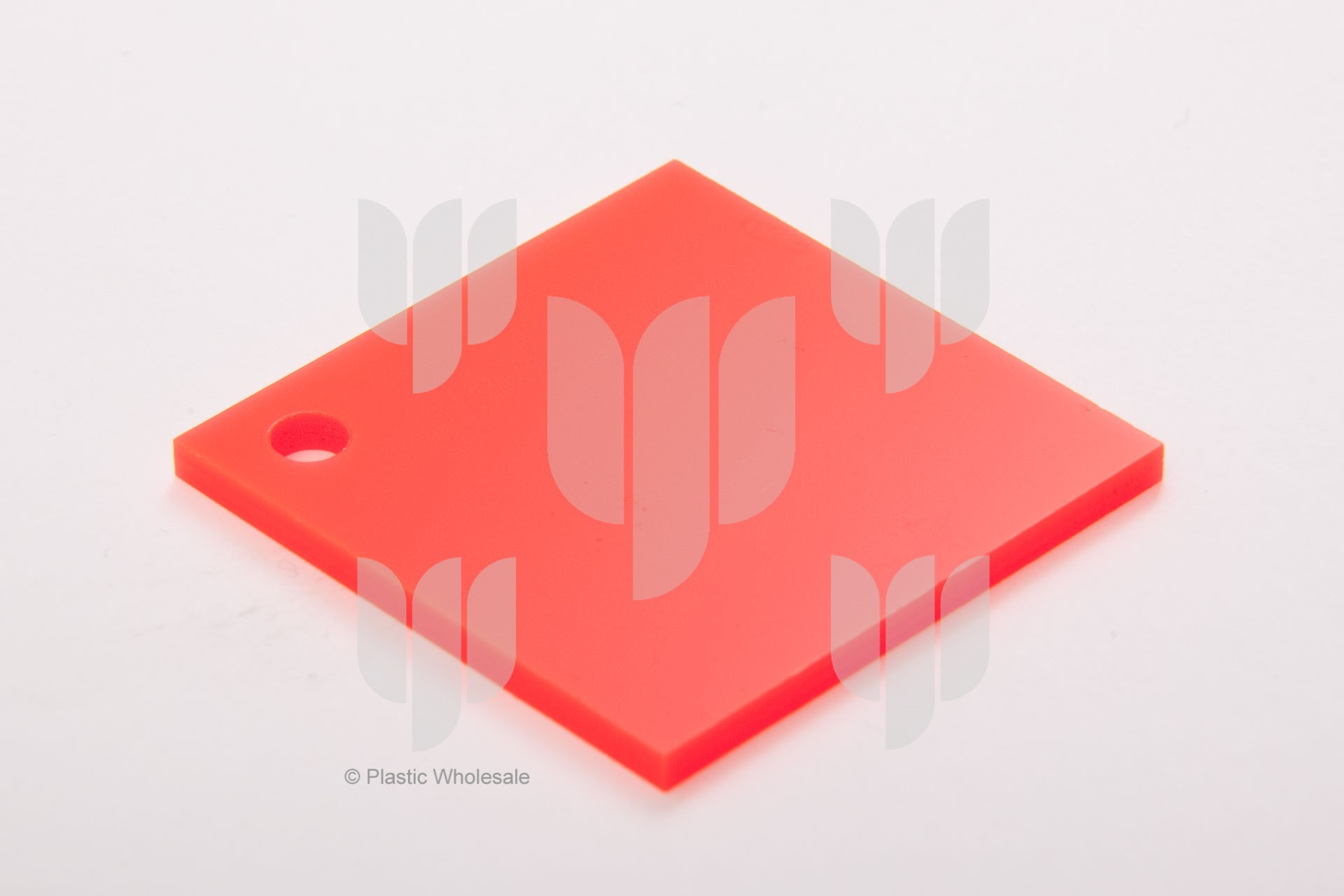

Acrylic, also known by European brands such as Plexiglas® and Perspex® is a transparent thermoplastic that is often chosen as a light, durable and cost-effective replacement for glass. It is approximately 17 times stronger than glass, weather resistant, easy to cut and shape, and shatter-resistant, making it safer than glass and suitable for a wider range of applications, from aquariums to retail signs and glass substitutes. It is also used as an economical alternative to polycarbonate. Plexiglas® is a registered trademark of Röhm GmbH, Darmstadt, Germany. Perspex® is a registered trademark of Perspex International Ltd, Darwen, Lancashire, UK.

What is the difference between Acrylic and Perspex®

Perspex® is a brand name of acrylic sheet. Acrylic is a commonly used name for Polymethyl Methacrylate (PMMA) which is produced by numerous acrylic manufacturers around the world.

Does Plastic Wholesale supply the Perspex® brand?

Although we do not supply the Perspex® brand, we do supply acrylic sheets that are of comparable quality. We source our acrylic sheets from several leading manufacturers around the world to offer our customers the highest quality at affordable prices.

Installation Considerations

Although we don’t offer installation advice, there are some considerations to be aware of when working with acrylic. If you have questions regarding these issues, you would need to discuss the same with a builder, handyman or engineer or other qualified professional. The key considerations are:

- Drilling: customers often use a blunt drill bit to ensure that the sheet doesn’t ‘grab’, twist and crack. Some customers drill through timber ahead of drilling acrylic in order to reduce the sharpness of the drill bit. Additionally, customers sometimes drill a bigger hole than needed and then support the fixing (such as screws) with a rubber grommet. This takes pressure away from the holes, and reduces subsequent cracking, including due to expansion. Sometimes customers drill a small pilot hole ahead of drilling the larger hole in order to provide drilling stability as the surface is quite smooth and can be difficult to work with.

- Cutting: cutting is typically undertaken with a fine toothed blade. Customers use panel saws, jig saws, CNC routers, among others.

- Installing: where installation requires drilling holes, in addition to drilling a larger hole than needed and using a rubber grommet as mentioned previously, where appropriate customers sometimes support the acrylic sheet on the bottom with a small platform to reduce pressure on the holes, and thus reduce the risk of cracking, including from expansion. Where used, screws are typically tightened by hand rather than power drill to avoid over-tightening and cracking the sheet.

- Cleaning: warm soapy water and a soft cloth.

![]() Download datasheet (154Kb)

Download datasheet (154Kb)